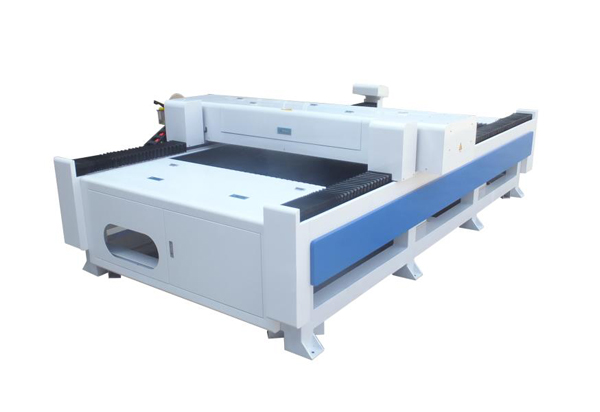

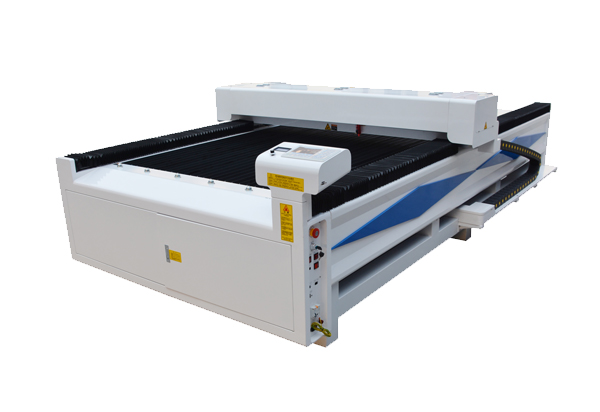

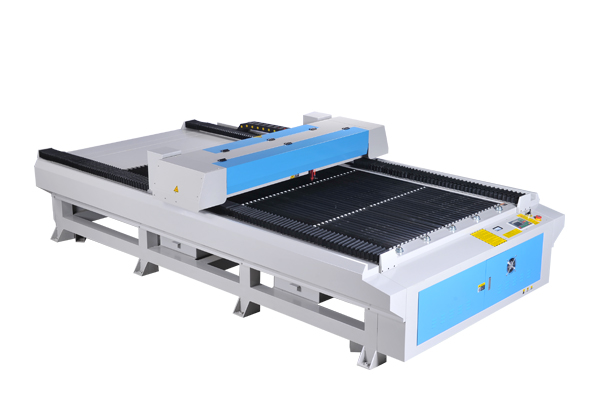

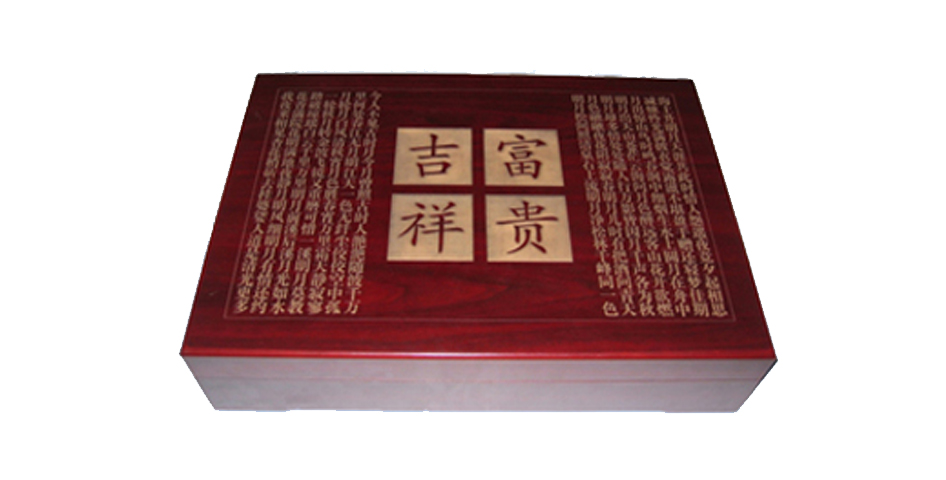

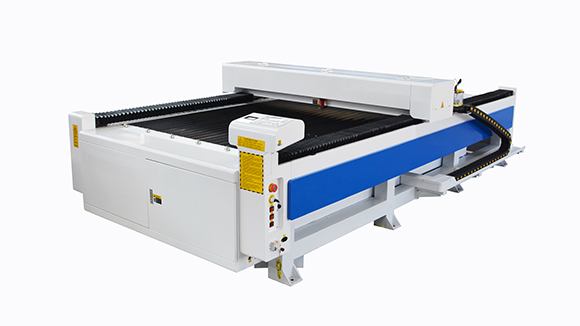

Popular searches: Laser engraving machine Laser cutting machine Auto feeding laser cutting machine CCD laser cutting machine Big size laser cutting machine laser cutting bed Fiber laser cutting machine Metal & nonmetal laser cutting machine Laser marking machine

All series of products·meet the needs of different industries

All series of products·meet the needs of different industries

The service hotline

The service hotline

Provide you with a complete set of lasertechnology solutions

Provide you with a complete set of lasertechnology solutions

Enterprise style

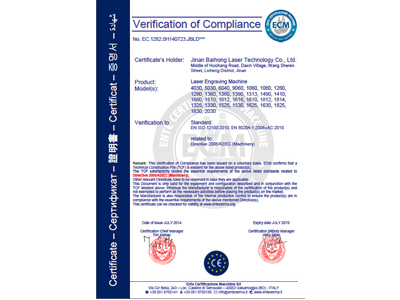

Enterprise style Honor of qualification

Honor of qualification

鲁公网安备 37011202001048号

鲁公网安备 37011202001048号

在线客服

在线客服